The petro-chemical industry is one of the most energy-intensive sectors in South Africa. From continuous production lines, high-pressure systems, flaring equipment to critical controls and safety systems, power failure or instability isn’t just inconvenient, it can quickly become catastrophic.

That’s why the move to renewable power and modern inverters is no longer just about “green credentials”. It’s about operational reliability, compliance, and risk-management.

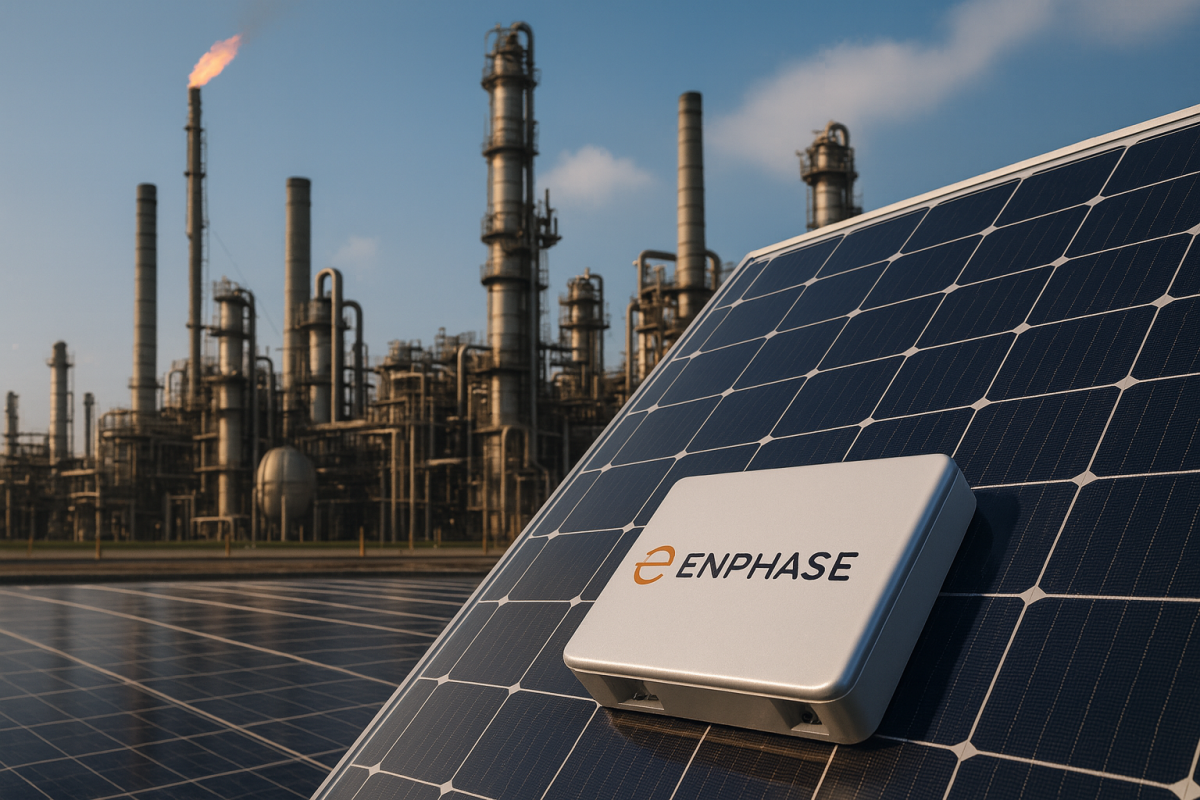

With Enphase microinverter-based solar systems (and hybrid battery storage) industrial operators now have access to technology that can meet these high demands. At JUP Solutions we’re helping petro-chemical plants, fuel terminals and associated heavy-industry facilities adopt these systems. Here’s how and why.

Why the Petro-Chemical Industry Needs Better Power Dynamics

- Demand for continuous uptime

Typical petro-chemical sites require power 24/7. Even short outages can halt critical systems, trigger safety protocols, cause product losses, or require expensive restart procedures. - Energy cost pressures & regulation

These facilities are heavy electricity consumers and face escalating tariffs, grid instability and increasingly stringent ESG / emissions regulation. Many are being assessed by financiers, insurers and major customers on their energy resilience. - Safety & fire-risk sensitivities

A site running flares, high-voltage equipment and combustible materials cannot tolerate power system instability or wiring failures. High-voltage DC runs across large roofs or exposed panels present added risk. - Opportunity for solar + storage

Large roofs, behaviour patterns, daytime-heavy loads and captive energy demands make petro-chemical plants well placed for solar PV + hybrid systems. But it must be done right—industrial grade, safe, scalable and monitored.

✅ How Enphase Technology Aligns with Industrial Needs

• Panel-Level Microinverters

Unlike traditional string inverters with long DC runs, Enphase microinverters convert DC to AC at each panel. That means no high-voltage DC bus, which helps reduce fire-risk and mitigates arc fault potential.

• Commercial/Three-Phase Solutions

Enphase’s newer commercial microinverters support three-phase, higher power output (eg: the IQ9N-3P series) designed for industrial scale deployments, with efficiency up to 97.5% and support for large modules.

• Safety, Monitoring & Assurance

With panel-level data, real-time monitoring and built-in rapid shutdown, Enphase meets high industrial safety standards. For petro-chemical operations this helps with continuity planning, hazard mitigation and asset protection.

• Scalability & Modular Growth

Plants may begin with a roof-mounted solar solution, then add battery storage, hybrid switching or integration with standby UPS/generator systems. Enphase’s modular architecture supports phased deployment and upgrades.

• Proven in Safety-Critical Sites

For example, Enphase microinverters have been deployed in gas station sites (a high-risk environment) globally, showing their suitability for fuel/chemical contexts.

Application Examples in Petro-/Chemical Sector

- Daytime-production offset: A chemical processing line runs primarily during sunlight hours. A solar + Enphase system can offset grid consumption and reduce peak tariff exposure.

- Battery backup for critical systems: When grid fails, critical safety, control systems, flaring instrumentation or cooling systems remain powered via battery/hybrid system, reducing outage risk.

- Roof arrays for ancillary buildings: Warehouses, labs, offices on site fitted with microinverters for high reliability, returning value on under-utilised roof space.

- ESG & carbon visibility: With monitoring, the site can produce data for CO₂-saved, energy independence and supply chain compliance – valuable for reporting and contracting.

Business Case: Why It Makes Financial Sense

- Reduced grid usage during peak hours lowers energy cost base.

- Avoided downtime has high value: an hour’s outage in a petro-chemical context can cost tens to hundreds of thousands of Rands.

- Reduced fire/hazard risk means fewer insurance surprises and compliance costs.

- Enhanced brand & supply-chain standing: Operators that demonstrate resilient, clean energy systems are increasingly preferred by customers and investors.

Thus, investing in an Enphase-powered system is more than “installing solar” – it becomes a strategic asset.

How JUP Solutions Can Help Your Site

At JUP Solutions we bring together:

- Industrial energy audits and load-profiles specific to petro-chemical plants.

- Design of solar arrays + Enphase microinverter systems with three-phase architecture and battery hybrid options.

- Integration with backup UPS and generator systems for full resilience.

- Monitoring dashboards, performance tracking and maintenance planning.

- Support for ESG reporting, carbon credits and regulatory compliance.

We’ve done this for manufacturing, logistics, fuel‐retail, and now we’re applying the same rigor to petro-chemical and process-industry plants.

When your operations depend on continuous, safe, efficient power – second-tier solar or mediocre inverters won’t cut it. You need solutions built for safety, reliability and industrial scale.

Enphase microinverter systems deliver exactly that and when paired with JUP Solutions, you get strategic engineering, industrial compliance and resilience.

Let’s help you transform energy from a cost liability into a tactical advantage.

Share this Post